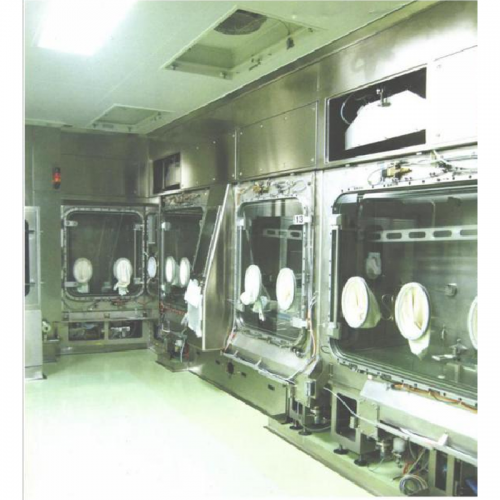

Transfer window is an auxiliary equipment in clean rooms, mainly used for the transfer of small items between clean rooms and between clean rooms and non clean rooms, in order to reduce the impact on clean rooms

Number of door openings. Transmitting windows are widely used in electronic technology, biological laboratories, pharmaceutical factories, hospitals, crystal processing industries, and other places. Transfer windows include sterile transfer windows, sterile laminar flow transfer windows, and air shower transfer windows.;

Characteristic:

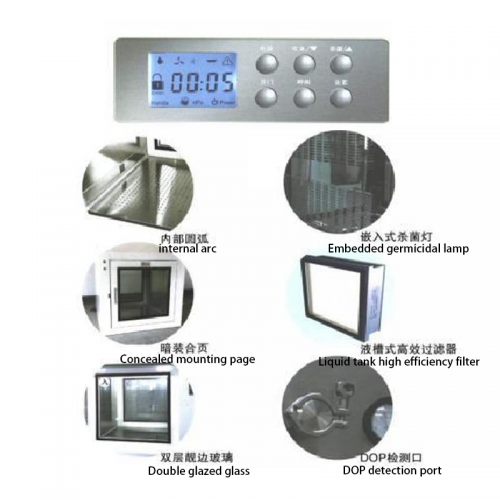

- Stainless steel 304 material, with an overall circular arc structure inside, easy to clean;

- Equipped with PAO injection interface and testing interface, using 304 stainless steel quick connector;

- Configure H14 liquid tank sealed high-efficiency filter with high-efficiency differential pressure gauge;

- Equipped with ultraviolet sterilization lamp, the sterilization time can be adjusted freely, and it also has sterilization timing and sterilization time accumulation function. It can be set whether the sterilization lamp starts at the same time as the fan at will;

- Independently developed LCD panel controller with two magnetic locks interlocked, with automatic and manual modes for users to set. In automatic mode, there are multiple functions that users can set themselves, including time and function display, and call function;

- The automatic start of the fan supply mode after closing the door can be set arbitrarily;

Embedded door, double-layer black edged tempered glass, with desiccant; - Fan: Customized dedicated fan with adjustable air supply time;

Design a fresh air inlet (located in the high clean area) to increase internal positive pressure and adjust the fresh air volume. Accept special designs from users.

Xinlei Stainless Steel Products Company was established in 2002 with a registered capital of 10 million yuan.

Our company has long been committed to providing pharmaceutical companies with stainless steel clean furniture and stainless steel products that meet GMP certification requirements, as well as pipeline laboratory design and installation. We are a professional and high-end supplier of stainless steel products and equipment. The company integrates development, production, and sales, committed to providing one-stop services for the pharmaceutical and related industries.

We have 15 professional designers of stainless steel clean furniture and stainless steel products that meet GMP certification requirements, and more than 50 senior technical personnel engaged in cutting, bending, splicing, welding, and polishing of stainless steel clean furniture. We have advanced production equipment such as laser cutting equipment, laser cutting equipment, imported bending machines, and several imported and domestic laser welding machines. Having a special equipment (pressure vessel) manufacturing license and GC2 pressure pipeline certificate

Our aim is to persevere and continue to welcome your arrival with better products and higher quality services.

评价

目前还没有评价